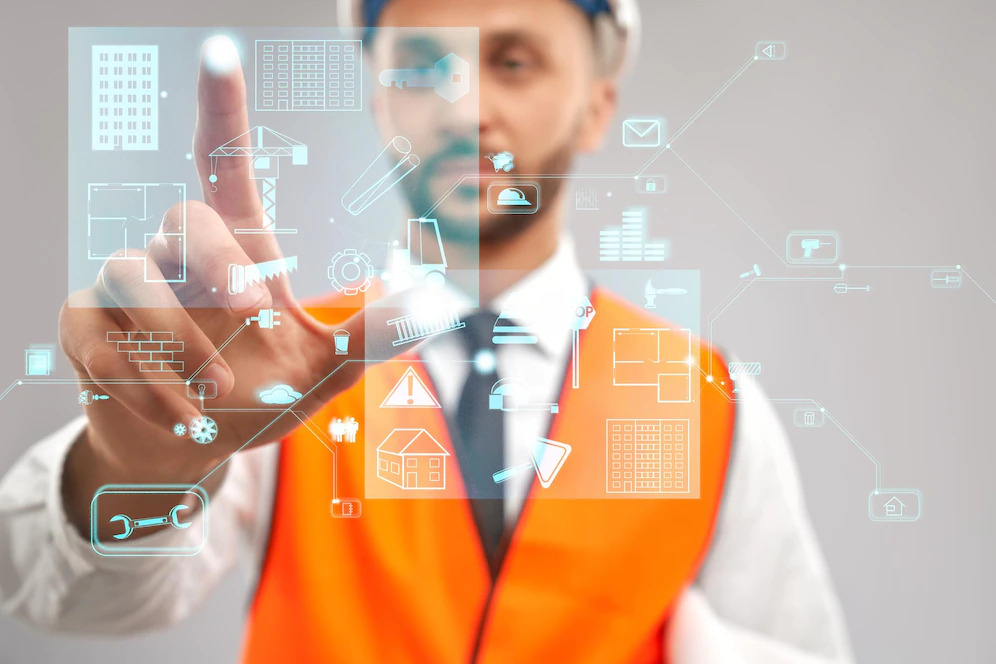

Structural audit is an examination of the overall health of a building to ensure that it is safe, risk-free and habitable.

Our team of Experts will arrive at your location and do a brief survey of the structure to be audited and after getting work order, commencement of tests will occur.

Model bye-law no. 77 specifies Structural Audit as a mandatory requirement. It stipulates that if the age of a building is 15 to 30 years, Structural Audit must be carried out once in 5 years and for buildings older than 30 years it must be carried out once in 3 years. You may, however, go for it even earlier if you suspect the condition of your building to be bad.

With every passing year, your building combats a series of natural upheavals, facing the apathy of every season that goes by. Many buildings built during last 20 to 25 years in India are in severe structural distress. Leakages are a common sight during monsoons. To add to this, we keep hearing of sporadic incidents of building collapse, which have resulted in irreparable loses at times, both of men and material. And that’s when the concept of ‘structural audit’ became known and it was soon made mandatory to be followed.

TESTS DONE BY OUR TEAM

The structural integrity of a building is initially determined by the visual inspection; however, the strength and durability of concrete is an essential factor that decides its longevity and safety. For this purpose, non-destructive testing (NDT) should be carried out to check concrete strength, chemical attack resistance, corrosion assessment, among other things. Below are the common techniques to assess whether your building’s concrete will stand the test of time.

- Rebound Hammer Test on beams, slabs, etc. to check the compressive strength of the concrete.

- Ultrasonic Pulse Velocity Test to inspect cracks and to test the quality of concrete and natural rocks in the building.

- Core testing consists of a method in which samples are tested in a laboratory to determine strength.

- Chemical tests are performed to check carbonation and pH, water/acid soluble chloride and sulphate contents of the concrete.

- Rebar locators and cover meters are used to check the cover, diameter and reinforcement of steel

- Water permeability test is carried out to check the resistance of concrete under water pressure.

- Half-cell potential test is done to check corrosion or the possibility of it in the steel.

- Slab Load Test are performed

- Earthquake resistance (seismic diagnosis test) and fire readiness (firefighting system analysis) is measured and analysed by the structural auditors in addition to the above mentioned tests.

Our Projects

New Technologies in Focus

RAP a Sustainable Opportunity

Full Depth Recycling (FDR)

Cold Mix Technologies

Hot in Place Recycling

Hot in Plant Recycling

Application of Industrial Byproducts

Maintenance Strategies

Crack Sealing

Micro Surfacing

Retrofitting

Our clients